March 25 Update: I continue to update and modify this post, usually at the end, unless noted as Update in the middle (just a couple).

After seeing the N95 shortage gripping the nation’s healthcare workers, HP Inc. and partners have mobilized to create 3D printed face mask and face shield solutions, plus a few other innovative ideas, to keep people safe during the COVID-19 outbreak.

HP is, of course, one of the largest and best known companies in the world, putting their enormous might alongside other efforts to create alternate personal protection equipment (PPE) is significant (and needed). However, they are not the only ones doing this and I will share a number of initiatives taking place from small to large (including some of the ones I mentioned in the DIY Face Mask post as well as the N95 Mask post).

Update: I forgot to mention Materialise as one of HP’s partners and they created a number of free to download files for COVID-19 prevention, including the Hands-Free 3D-Printed Door Opener found on the HP site above, plus a Shopping Cart Handle.

This ongoing GoFundMe: Save Lives w 3D Printed Face Shields is impressive and inspiring — this is a team of high school students in the Charlotte Latin School covering K-12 with a FabLab. Read their mission and overview and tell me you are not blown away by the effort these young people are making (led by two MD parents with children at the school).

In support of the #MillionMaskChallenge on Twitter, the engineering team at Charlotte Latin intend to 3D print face shields that will be provided to local hospitals in Charlotte, starting with the Levine Cancer Institute. The goal? To manufacture 10,000 face shields. Bravo.

MatterHackers, the largest distributor of desktop digital manufacturing equipment and materials in the USA, is arguably one of the dominant 3D printing voices in social media and they often rally behind various community initiatives. I am not surprised to see them drop everything and hit this virus with everything they can. Dave Gaylord, Chief Technical Officer, comes from a Medical Device R&D and manufacturing background and is passionately ensuring MatterHackers connects those in need with those who can make.

The MatterHackers initiative is called the COVID-19 Additive Manufacturing Community Response Hub and it will “connect those in the U.S. who need medical aid (Hospitals and Govt. Agencies) and those who can create it using Digital Manufacturing, for which MatterHackers has a broad base of customers to engage with.” It has been live for three days and hundreds have signed up.

Formlabs has an impressive medical capability with its 3D printers (before COVID-19) and opened up its networks and printers to help with a tiny item of critical concern to the medical community: COVID-19 Test Kit Swabs (Check out the detailed photo below). The site lists out several designs. Their PR rep messaged me to say:

“Formlabs is mobilizing its community of users to deploy nearly 1,000 printers to quickly mass-produce these swabs as well as other important personal protective equipment (PPE). A single print can produce 300 test swabs at a time enabling Formlabs to produce 75,000-150,000 swabs per day. This development will rapidly provide hospitals with access to large quantities of these essential COVID-19 test kit components.”

Joel Telling, a well-known YouTuber in 3D printing, who is frequently reviewing 3Dprinters and sharing his technical expertise. He opened with this video earlier this week to share a timely message and encourage those who are wanting to make a difference from their shops. He interrupts his regularly scheduled broadcast with: 3D Printing Respirator Valves for Coronavirus AND How YOU Can Help!. Plus, he lists a bunch of additional efforts going on that I couldn’t include.

Many of the people and companies listed here had planned to gather in a few weeks at the largest 3D printing show, RAPID + TCT. I also had purchased my airline ticket when the parent organization, SME, wisely postponed the event like so many others. I have attended several of the RAPID + TCT events and it is always amazing to connect with the community; it is more like a large family reunion, frankly.

Although it was disappointing for the Coronavirus to put the brakes on large, in-person gatherings, it allowed many of the top companies to get a grip on how to tackle this pandemic. All of the usual energy and enthusiasm you might have experienced at RAPID + TCT is now pouring into virtual work and collaborating. People are channeling all of that into helping to solve COVID-19 problems for healthcare workers. If you ever wondered if 3D printing is all it claims to be, Coronavirus has helped settle that. 3D printers do all of this and more.

Disclosure: I was scheduled to be at RAPID to do a few paid blog posts for SME. The upside is that even with the event cancelling I was able to reconnect with a bunch of lost contacts and some of them are here because of that. As someone who has worked extensively in this industry, it is hard for me to avoid current and past clients in my writing, but when a relationship exists I disclose it.

One of the biggest voices through all of these rapid changes has been Joseph Prusa, maker of the Original Prusa i3 MK3S 3D printer, and well-known for his commitment to the 3D printing community as a whole, including researching solutions at warp speed to make a difference in this COVID-19 crisis. After seeing a number of projects trying to help healthcare workers, he laid out a position that face shields was the way to go: From Design to Mass 3D printing of Medical Shields in Three Days. He then shared his design with instructions and files: Prusa Protective Face Shield - RC2.

I want to wrap this post up by sharing the heartfelt message (as he explains he has two siblings in the thick of it in Spain) of Enrique Lores, President & CEO, HP Inc. in a news release today: “I know these are difficult and uncertain times… Healthcare workers on the frontlines, as well as all of us at home, must come together to mitigate the spread of COVID-19 around the globe... We will not let them down.”

More Projects & Resources:

Hackaday: MIT Ventilator Designed With Common Manual Resuscitator Submitted For FDA Testing. “MIT is working on FDA approval of an emergency ventilator system (E-Vent). They have submitted the design to the FDA for fast track review. The project is open source, so once they have approval the team will release all the data needed to replicate it.” Keep track of their work if you are intent on open source ventilators.

At Tennessee Tech University, Dr. Ismail Fidan and team have printed 381 masks that went to the state directly for distribution. They are running 30 3D printers across two labs. (Disclosure: I’ve worked on blog posts for Dr. Fidan for a National Science Foundation grant project publication where I am editor).

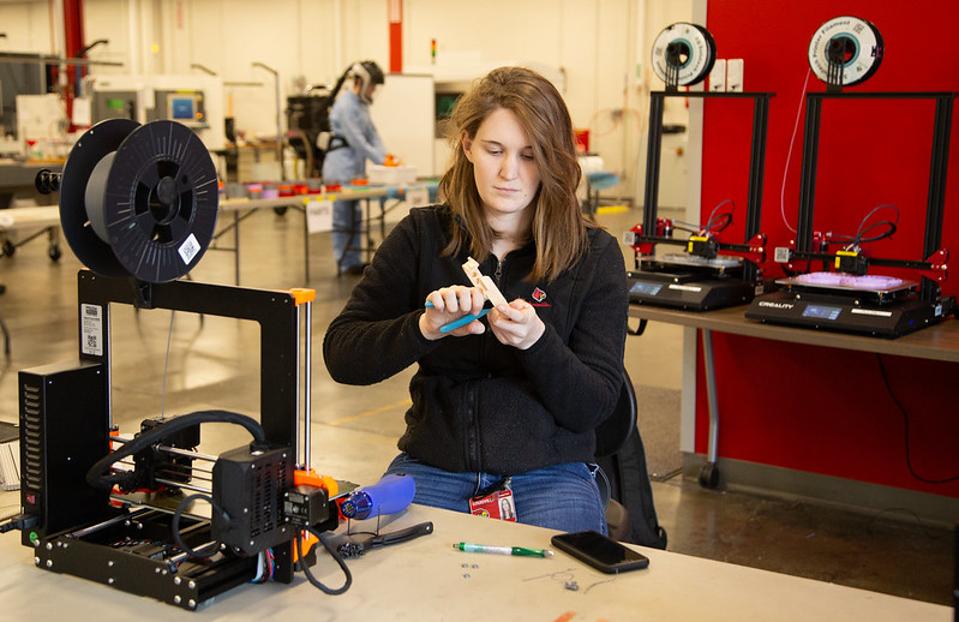

University of Louisville runs one of the top Additive Manufacturing programs and has an amazing 3D printing facility. I know because I visited Ed Tackett who runs it a few years back when I happened to be driving across the country (not 3DRV, another time). You can read more about their COVID-19 efforts here: Students Producing 3D Printed Face Shields For Healthcare Professionals.

If you need more technical, academic study type data, check out this page from the National Center for Biotechnology Information. Here’s one, for example: Modeling the Effectiveness of Respiratory Protective Devices in Reducing Influenza Outbreak.

This is very informative and intersting for those who are interested in share market field.

ReplyDeleteIT/ITES

Walmart

TCS target price

EaseMyTrip

I am a regular reader of your blog, Amazing content with proper examples. Thank you admin. 3D printing service

ReplyDeleteWell this is awesome post and written very well. Your point of view is very good. Are you looking for top quality printing services at genuine rates? Contact us today!

ReplyDeleteInteresting topic for a blog. I have been searching the Internet for fun and came upon your website. Fabulous post. Thanks a ton for sharing your knowledge! It is great to see that some people still put in an effort into managing their websites. I'll be sure to check back again real soon. renting impresoras zaragoza

ReplyDelete